Printable Heat Transfer

adminse

Apr 04, 2025 · 8 min read

Table of Contents

Unlock the Power of Print: A Deep Dive into Printable Heat Transfer

What if you could transform ordinary fabrics into personalized masterpieces with the simple click of a button? Printable heat transfer technology is revolutionizing customization, offering unparalleled creative freedom and accessibility.

Editor’s Note: This comprehensive guide to printable heat transfer was published today, providing readers with the latest insights and techniques in this exciting field. Whether you're a seasoned crafter, a budding entrepreneur, or simply curious about this transformative technology, this article will equip you with the knowledge and understanding you need to harness its potential.

Why Printable Heat Transfer Matters:

Printable heat transfer is transforming the way individuals and businesses approach personalization and design. From customized apparel and accessories to unique home décor, its applications are vast and continuously expanding. This technology democratizes the design process, allowing anyone with access to a printer to create professional-looking, durable prints on a variety of fabrics. Its impact spans diverse industries, including fashion, promotional products, crafting, and even industrial applications, contributing to increased efficiency and reduced production costs.

Overview: What This Article Covers:

This article provides a comprehensive exploration of printable heat transfer, covering its various types, application methods, design considerations, troubleshooting tips, and future trends. We will examine the different printable heat transfer papers available, explore the advantages and disadvantages of each type, and provide actionable advice for achieving optimal results. Readers will gain a deep understanding of this technology, enabling them to confidently embark on their own heat transfer projects.

The Research and Effort Behind the Insights:

This article is the product of extensive research, drawing upon industry best practices, expert opinions from leading heat transfer manufacturers, and analysis of numerous user experiences and online resources. We've scrutinized various techniques and materials to provide readers with accurate, actionable information and reliable troubleshooting guidance.

Key Takeaways:

- Definition and Core Concepts: A clear understanding of printable heat transfer, including its different types and applications.

- Paper Selection: Guidance on choosing the right printable heat transfer paper for various fabric types and desired results.

- Design Considerations: Tips for creating high-quality designs optimized for heat transfer printing.

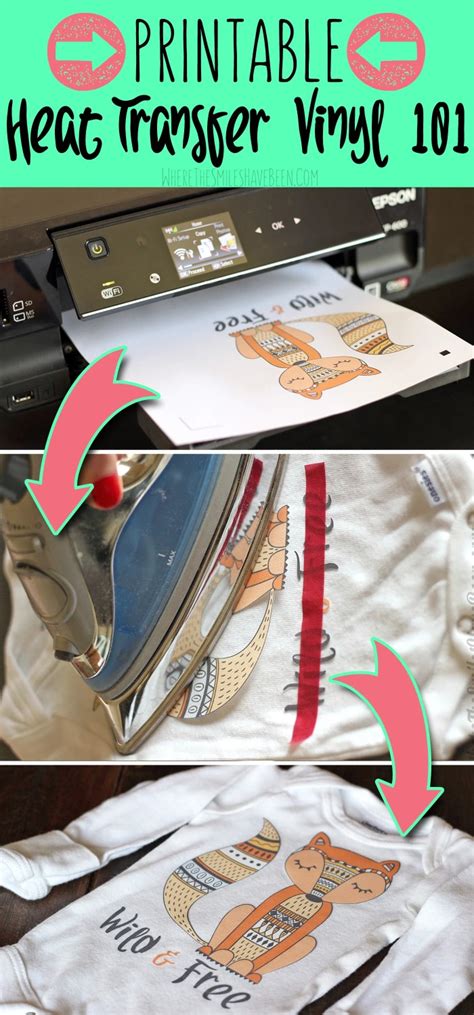

- Application Techniques: Step-by-step instructions for applying heat transfer prints to different fabrics.

- Troubleshooting: Solutions to common problems encountered during the heat transfer process.

- Advanced Techniques: Exploration of specialized techniques and applications for advanced users.

- Sustainability and Eco-Friendly Options: Discussion of environmentally conscious choices in printable heat transfer.

Smooth Transition to the Core Discussion:

Now that we’ve established the significance of printable heat transfer, let’s delve into the specifics, beginning with a detailed exploration of the different types of printable heat transfer papers available.

Exploring the Key Aspects of Printable Heat Transfer:

1. Definition and Core Concepts:

Printable heat transfer is a process that uses specially designed paper to transfer printed images onto fabrics. This paper has a coating that bonds with the fabric when heat and pressure are applied. The process eliminates the need for screen printing or other specialized equipment, making it accessible to a broader audience. The printed image is essentially "mirrored" onto the transfer paper so that when pressed onto the garment, the correct image appears.

2. Types of Printable Heat Transfer Paper:

Several types of printable heat transfer paper cater to various needs and fabric types:

- Iron-On Transfer Paper: This is the most common type, designed for use with a household iron. It's generally suitable for cotton, polyester blends, and other fabrics with a smooth surface. It comes in variations offering different levels of durability and washability.

- Heat Press Transfer Paper: This paper requires a heat press machine for application, providing more even heat distribution and pressure for superior results, particularly on harder-to-press materials. Heat press transfer papers usually offer greater durability and are better suited for dark-colored fabrics.

- Sublimation Transfer Paper: This specialized paper uses a sublimation printing process, where the ink transforms into a gas and becomes permanently embedded into the fabric fibers. Sublimation is ideal for polyester fabrics and allows for exceptionally vibrant and long-lasting prints. However, it requires a specialized sublimation printer and heat press.

3. Applications Across Industries:

Printable heat transfer's versatility makes it a valuable asset across various industries:

- Apparel Customization: Creating personalized t-shirts, hoodies, tote bags, and other apparel items.

- Promotional Products: Personalizing items like mugs, mouse pads, and phone cases for promotional campaigns.

- Crafting and DIY Projects: Adding custom designs to fabric crafts, scrapbooking materials, and other handmade items.

- Industrial Applications: Producing customized labels, patches, and other markings for industrial products.

4. Challenges and Solutions:

Despite its advantages, certain challenges can be encountered with printable heat transfer:

- Image Cracking or Peeling: This can occur due to improper application, inadequate heat or pressure, or using the wrong type of paper for the fabric. Using a heat press and correct temperature/time settings minimizes this risk.

- Color Bleeding or Fading: This is more likely with iron-on transfers and can be mitigated by using high-quality ink and proper pre-treatment of the fabric.

- Wrinkling or Distortion: This can result from uneven pressure during application. Using a heat press or applying consistent, even pressure with an iron minimizes this issue.

5. Impact on Innovation:

Printable heat transfer is continually evolving, with new papers, inks, and techniques emerging to enhance print quality, durability, and application ease. The accessibility of this technology encourages creativity and innovation, allowing individuals and businesses to explore personalized designs previously inaccessible without specialized equipment.

Closing Insights: Summarizing the Core Discussion

Printable heat transfer empowers individuals and businesses to create personalized and high-quality designs on various fabrics with relative ease. By understanding the different types of transfer paper and application techniques, one can overcome potential challenges and achieve professional-looking results.

Exploring the Connection Between Design Software and Printable Heat Transfer:

The relationship between design software and printable heat transfer is paramount. The quality of the final product hinges significantly on the design process.

Key Factors to Consider:

- Roles and Real-World Examples: Design software allows for creating intricate designs, manipulating images, and adding text effects – crucial elements for personalized heat transfer projects. Software such as Adobe Photoshop, Illustrator, or even simpler online tools can transform a simple idea into a high-resolution print ready for transfer.

- Risks and Mitigations: Using low-resolution images or improper file formats can lead to poor print quality. Understanding the resolution requirements of the transfer paper and ensuring the correct file format (e.g., PDF, PNG) are crucial to avoid issues.

- Impact and Implications: High-quality design software enhances the potential of heat transfer, enabling the creation of detailed, professional-looking prints which elevate the overall aesthetic of the final product.

Conclusion: Reinforcing the Connection

Effective design software is indispensable for maximizing the potential of printable heat transfer. By understanding and leveraging the capabilities of design programs, individuals and businesses can elevate their heat transfer projects, achieving outstanding results.

Further Analysis: Examining Design Software in Greater Detail:

The choice of design software depends on the user's skill level and project complexity. For simple designs, online tools are sufficient. However, for intricate designs and precise control over color and details, professional software like Adobe Creative Suite is recommended. Understanding the color profiles, image resolution, and file export settings is crucial for optimal results.

FAQ Section: Answering Common Questions About Printable Heat Transfer:

Q: What type of printer is needed for printable heat transfer paper?

A: Most iron-on transfer papers are compatible with inkjet printers. Sublimation transfer paper requires a specialized sublimation printer.

Q: Can I use printable heat transfer paper on all fabrics?

A: No, different types of transfer paper are suitable for different fabrics. Check the manufacturer's instructions for compatibility.

Q: How long do heat transfer prints last?

A: The durability of the print depends on the type of paper, application method, and fabric care. High-quality prints can last for many washes, provided proper care instructions are followed.

Q: What if my print cracks or peels?

A: This is often due to insufficient heat or pressure during application or using the wrong type of paper. Ensure you're following the manufacturer's instructions precisely.

Practical Tips: Maximizing the Benefits of Printable Heat Transfer:

- Choose the Right Paper: Select the paper type that matches your printer and fabric.

- Design High-Resolution Images: Use high-resolution images to avoid pixelation in the final print.

- Mirror Your Image: Remember to mirror your design before printing, as the image is reversed when transferred.

- Use a Heat Press (if possible): A heat press provides more even heat and pressure than an iron, leading to superior results.

- Follow Application Instructions: Carefully follow the manufacturer's instructions for application temperature, time, and pressure.

Final Conclusion: Wrapping Up with Lasting Insights:

Printable heat transfer is a powerful and accessible technology that empowers creativity and personalization. By understanding its principles, choosing the right materials, and mastering the application techniques, you can unlock a world of design possibilities, transforming ordinary fabrics into extraordinary creations. The continuous advancements in this field ensure that the potential of printable heat transfer will only continue to grow, offering even greater opportunities for innovation and customization in the years to come.

Latest Posts

Latest Posts

-

Printable Leopard Gecko Care Sheet

Apr 05, 2025

-

Printable Lenten Calendars

Apr 05, 2025

-

Printable Lenten Calendar

Apr 05, 2025

-

Printable Lent Calendar

Apr 05, 2025

-

Printable Lemons

Apr 05, 2025

Related Post

Thank you for visiting our website which covers about Printable Heat Transfer . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.