Printable Welding Symbols Chart

adminse

Apr 07, 2025 · 7 min read

Table of Contents

Unlocking the Secrets of Welding: A Comprehensive Guide to Printable Welding Symbols Charts

What if understanding welding symbols could unlock a world of efficient and safe fabrication? A mastery of these symbols is the key to clear communication and flawless welds.

Editor’s Note: This article on printable welding symbols charts has been updated today to reflect the latest industry standards and best practices. This guide provides a detailed understanding of these crucial symbols, empowering welders, engineers, and fabricators alike.

Why Printable Welding Symbols Charts Matter:

Welding symbols are the universal language of the welding industry. They provide a concise and unambiguous way to communicate complex welding instructions, eliminating misunderstandings and ensuring consistent, high-quality welds. A printable chart serves as a readily available reference, improving efficiency and reducing errors on the shop floor, in the classroom, or even at home for personal projects. Their importance extends across various sectors, including construction, manufacturing, aerospace, and automotive industries. Proper interpretation directly impacts safety, cost-effectiveness, and the overall structural integrity of welded components.

Overview: What This Article Covers:

This article offers a comprehensive exploration of printable welding symbols charts. We will delve into the basic structure of a welding symbol, examining each component and its significance. We will then explore different types of welding processes, weld features, and how they are represented symbolically. Finally, we'll discuss the practical applications of these charts, address frequently asked questions, and offer tips for maximizing their utility.

The Research and Effort Behind the Insights:

This article is the result of extensive research, drawing upon the American Welding Society (AWS) standards, industry best practices, and real-world applications of welding symbols. We have consulted numerous technical manuals, online resources, and expert opinions to ensure accuracy and provide readers with a trustworthy and reliable guide.

Key Takeaways:

- Definition and Core Concepts: A detailed explanation of the basic structure of a welding symbol and its key components.

- Types of Welds: Identification and symbolic representation of various weld types, including fillet welds, groove welds, and spot welds.

- Weld Features: Understanding symbols for weld dimensions, surface conditions, and other critical features.

- Process Specifications: How welding processes are indicated on the symbol.

- Practical Applications: Real-world examples demonstrating the use of welding symbols in various projects.

- Challenges and Solutions: Addressing common misunderstandings and providing strategies for accurate interpretation.

- Printable Chart Usage: Tips and best practices for effectively using printable welding symbols charts.

Smooth Transition to the Core Discussion:

With a firm understanding of the importance of welding symbols, let's delve into the detailed explanation of the components and their meaning within the standard welding symbol.

Exploring the Key Aspects of Printable Welding Symbols Charts:

1. Understanding the Basic Structure of a Welding Symbol:

The standard welding symbol, as defined by the AWS, is a highly structured graphic. It consists of several key elements:

- Reference Line: A horizontal line that forms the basis of the symbol.

- Arrow Side: The side of the reference line pointing towards the weld location. Symbols and specifications on this side apply to the component the arrow points to.

- Other Side: This side indicates specifications for the opposite component.

- Tail: An extension of the reference line, usually to the left, used for additional information.

- Basic Weld Symbols: These symbols indicate the type of weld (e.g., fillet, groove, spot).

- Supplementary Symbols: These symbols indicate specific weld features (e.g., weld size, contour, finish).

- Dimensioning and Specifications: Numerical data specifying weld size, length, spacing, etc.

2. Types of Welds and Their Symbolic Representation:

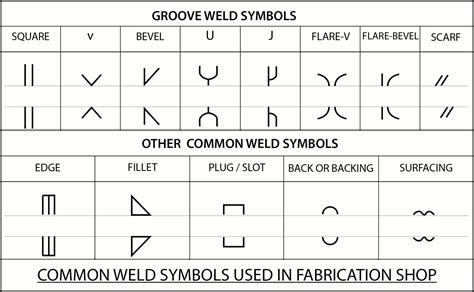

A printable chart typically illustrates a range of weld types:

- Fillet Welds: These welds join two members at an angle, forming a triangular shape. The symbol is a short, slanted line.

- Groove Welds: These welds are used to join two members edge-to-edge, creating a complete penetration. The symbol varies depending on the type of groove (e.g., V-groove, U-groove, bevel groove).

- Spot Welds: These welds are created using resistance welding, making small localized welds. The symbol is a small circle.

- Seam Welds: These are continuous spot welds used in sheet metal applications.

- Plug and Slot Welds: These are used to create welds in holes.

3. Weld Features and Their Symbolic Representation:

Beyond weld type, the symbol includes information about:

- Weld Size: The leg length (fillet) or throat depth (groove) is indicated by numbers on the symbol.

- Weld Length: The overall length of the weld is specified.

- Weld Spacing: The distance between multiple welds is indicated.

- Weld Contour: This indicates if the weld is convex, concave, or flush.

- Weld Finish: Specifications for surface cleaning or treatment are noted.

- Welding Process: The specific welding process used (e.g., GMAW, SMAW, GTAW) is designated by supplementary symbols or a process code.

4. Practical Applications:

Printable welding symbols charts are utilized extensively in:

- Welding Drawings: These charts are essential components of engineering drawings, providing crucial welding instructions.

- Weld Procedure Specifications (WPS): They aid in defining the exact parameters for a particular weld.

- Weld Qualification Tests (WQT): They ensure welders meet specific quality standards.

- Shop Floor Communication: They enable efficient communication between welders, inspectors, and engineers.

- Training and Education: They are invaluable tools in welding training programs.

5. Challenges and Solutions:

Common challenges include:

- Symbol Misinterpretation: Clear understanding of each symbol component is crucial.

- Missing or Ambiguous Information: Drawings must be complete and unambiguous.

- Outdated Standards: Using the latest AWS standards ensures compliance.

Solutions include:

- Thorough Training: Proper training on AWS standards is essential.

- Clear Communication: Open dialogue between engineers and welders is vital.

- Regular Updates: Keeping charts updated with the latest standards is key.

Exploring the Connection Between Welding Procedure Specifications (WPS) and Printable Welding Symbols Charts:

WPS documents provide detailed parameters for specific welds, and the welding symbol chart is a visual representation of these parameters. The chart directly translates the critical information from the WPS into a readily understandable format for the welder.

Key Factors to Consider:

- Roles and Real-World Examples: A WPS dictates the type of weld, size, process, and other parameters. The welding symbol then visually communicates this to the welder on the drawing, ensuring consistency with the WPS.

- Risks and Mitigations: Errors in the symbol can lead to incorrect welds, jeopardizing quality and safety. Careful review and cross-referencing with the WPS mitigate this risk.

- Impact and Implications: Accurate symbols ensure consistent weld quality, reducing rework, and improving overall project efficiency and safety.

Conclusion: Reinforcing the Connection:

The relationship between WPS documents and welding symbols charts is vital for successful welding projects. By meticulously ensuring the symbol accurately reflects the WPS, the potential for errors is significantly minimized, leading to better quality, improved safety, and increased efficiency.

Further Analysis: Examining AWS Standards in Greater Detail:

The American Welding Society (AWS) publishes comprehensive standards for welding symbols, ensuring consistency and clarity across the industry. These standards define the structure, components, and interpretation of welding symbols, providing a common language for communication between engineers, designers, and welders. Familiarity with these standards is crucial for anyone working with welding symbols.

FAQ Section: Answering Common Questions About Printable Welding Symbols Charts:

- What is a welding symbol? A welding symbol is a graphical representation of welding instructions, communicating the type, size, location, and other details of a weld.

- How are welding symbols used? They are included on engineering drawings to provide clear instructions to welders.

- What are the main components of a welding symbol? The key components include the reference line, arrow, tail, and various supplementary symbols.

- Where can I find printable welding symbols charts? These charts are available from various sources, including AWS, welding supply companies, and online resources.

- Are there different standards for welding symbols? While AWS standards are widely adopted, other national and international standards exist.

Practical Tips: Maximizing the Benefits of Printable Welding Symbols Charts:

- Laminate your chart: This protects it from wear and tear in the shop environment.

- Keep it readily accessible: Place the chart in a visible and convenient location.

- Regularly review the chart: Familiarize yourself with all symbols and their meanings.

- Use the chart in conjunction with WPS documents: Ensure the chart accurately reflects the specified parameters.

- Update your chart as needed: Stay current with the latest AWS standards.

Final Conclusion: Wrapping Up with Lasting Insights:

Printable welding symbols charts are invaluable tools for the welding industry. By understanding their structure, components, and applications, welders, engineers, and fabricators can significantly enhance communication, improve weld quality, ensure safety, and optimize overall project efficiency. Mastering this universal language is a key to success in welding. The effort invested in understanding these symbols translates directly into improved products, reduced costs, and a safer work environment.

Latest Posts

Latest Posts

-

Pumpkin Coloring Printable

Apr 08, 2025

-

Pumpkin Color Pages Printable

Apr 08, 2025

-

Pug Printable Coloring Pages

Apr 08, 2025

-

Ptcb Practice Exam Printable

Apr 08, 2025

-

Psu Football Schedule Printable

Apr 08, 2025

Related Post

Thank you for visiting our website which covers about Printable Welding Symbols Chart . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.